██████╗░░░░░░░░█████╗░░░░░░░██╗░░░██╗

██╔══██╗░░░░░░██╔══██╗░░░░░░██║░░░██║

██████╔╝█████╗██║░░██║█████╗╚██╗░██╔╝

██╔══██╗╚════╝██║░░██║╚════╝░╚████╔╝░

██║░░██║░░░░░░╚█████╔╝░░░░░░░░╚██╔╝░░

╚═╝░░╚═╝░░░░░░░╚════╝░░░░░░░░░░╚═╝░░░

The most detailed ROV article you can find on the entire internet.

Humankind is relentlessly striving to explore every corner of the universe, never content with a single goal. In this article, we will examine ROVs, cutting-edge technology used not only to access the depths of the seas but also to construct and retrieve objects. Similar robotic technologies are also used in space exploration, but unlike them, in this article, instead of ascending, we will descend. All the way to the bottom of the Mariana Trench.

The abbreviation ROV stands for “Remotely Operated Vehicle“. ROVs require a human operator to guide them. If they didn’t require an operator to perform their mission and could make their own decisions about their actions throughout the mission, we would call that vehicle an AUV, or autonomous underwater vehicle.

The first ROV in history

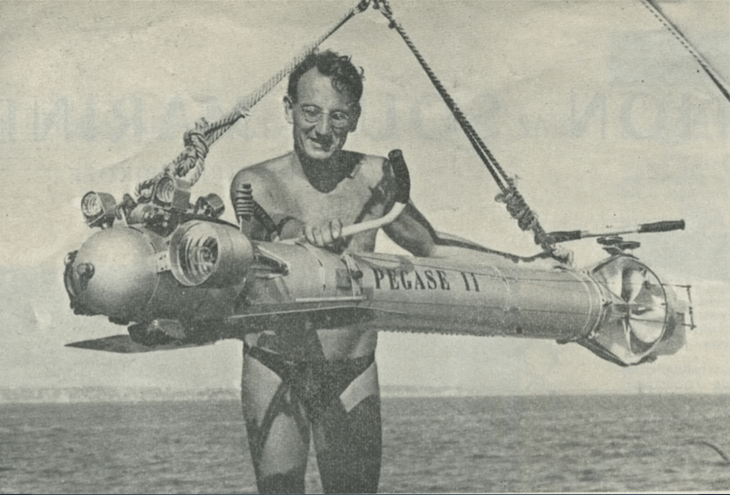

A pioneer in the development of diving equipment and underwater photography was the Poodle, a device developed in 1953 by French diver Dimitri Rebikoff. The Poddle was the result of Dimitri modifying his own dive scooter with tether and surface controls. Underwater vehicles such as the Pegasus and the Marine Inspector, also equipped with underwater cameras, were used by oil companies, the film industry, the US Oceanographic Office, and the US Navy.

Poodle

Pegasus

The Development of ROVs

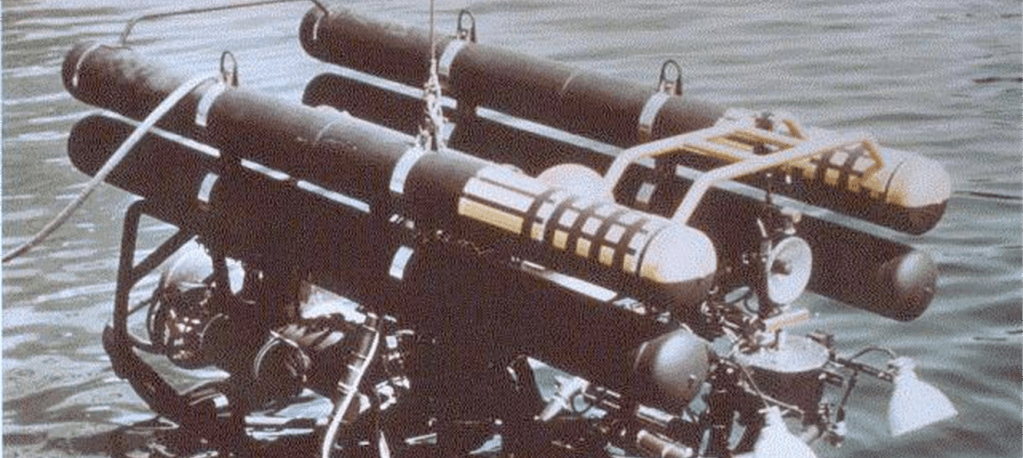

The US Navy funded much of the early development of ROV technologies in the 1960s, and from this development process emerged the Cable-Controlled Underwater Recovery Vehicle (CURV).

ROVs Of Today

Today, rovs are divided according to their classes and working methods.

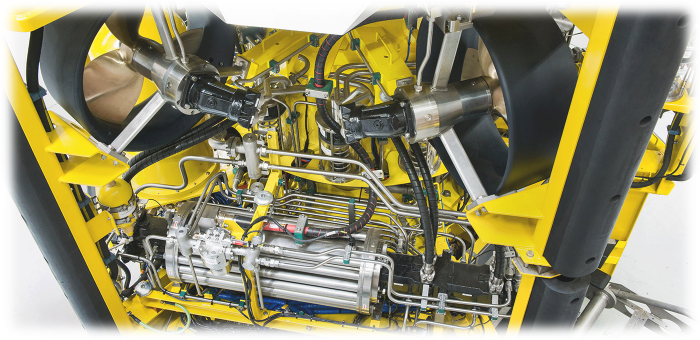

Hydraulic vs. electric

The main idea behind the desire to use electric thrusters is to eliminate the power losses in the piping system inherent in hydraulic systems.

The differences between them are briefly;

- Thrust motor size

Electric motors typically have larger dimensions than hydraulic thrust motors because they are housed in oil-filled housings. This increase in motor size restricts flow through one side of the thruster nozzle, creating resistance that causes the thruster to exert more thrust in one direction than the other.

The problem with electric designs in the past was that as ROVs got larger, so did their thrusters. This created a wave of shifts to hydraulic designs in the industry, relegating electrics to the background until today’s new technological advancements.

The standard process for workhorse ROVs is to use electrical power from the umbilical cord, which is converted into hydraulic power. This is an inefficient process that requires a lot of electrical power to provide an acceptable amount of hydraulic power.

- Robustness

In the event of a leak, the hydraulic thruster will continue to operate even if completely filled with seawater. In the same situation, an electric motor will short-circuit and fail. - Power ready for use

A hydraulic ROV has more power available for other tasks. For example, if a 100-horsepower hydraulic ROV uses only 10 horsepower to stay stationary in calm water, the remaining 90 horsepower can be used for other tools and auxiliary operations. An electric ROV is limited by the size of its auxiliary HPU (hydraulic power unit) and cannot transfer its propulsion to auxiliary tasks. - Ready-to-use components

Hydraulic motors have easier spare parts availability, while electric ROVs have fewer moving parts, making them easier and less expensive to maintain in the long run. - Peripheral equipment

Electric motors require additional support equipment that is both heavy and bulky. Storing these additional tools takes up extra storage space on the operating vehicle. - Environmental friendliness

Electric ROVs are more environmentally friendly. However, all ROVs, including those with electric thrusters, contain large volumes of hydraulic fluid. In sensitive operating environments, environmentally friendly hydraulic fluids can also be used to prevent potential leaks from harming marine life.

The primary reason for the current prominence of a modern class of electric ROVs is the industry’s interest in ultra-deep water.

This step into the future is actually a return to the past, when hydraulics are no longer an option for drilling at depths that current hydraulic ROVs cannot effectively reach. The primary reason for using all-electric ROVs in ultra-deepwater relates to the umbilical connection.

The umbilical cord connects the ROV cage to the crane and surface control equipment, provides power to the unit, provides back-and-forth communication between the operator and the ROV, and raises and lowers the ROV and its cage. To support the load and protect the power and communication lines inside, the umbilical cord is armored with a steel coating. This coating is protective, but it is also heavy. The larger the diameter of the umbilical cord, the heavier the armor. At high depths, the size of the umbilical cord required to transmit the necessary power to a hydraulic workhorse ROV requires an umbilical cord too heavy to support its own weight.

When steel can no longer do the job, this means switching to a lightweight alloy like titanium or Kevlar. Both alternatives are prohibitively expensive and present their own technical challenges. Going forward, the long-term solution will be a lower-power ROV to maintain an umbilical cord that can be armored with steel.

Currently, fully electric ROVs, which use the same system as hydraulic vehicles such as umbilical cords, cages and cranes currently on the market, are now reclaiming their place, once entrusted to hydraulic alternatives.

ROV CLASSES

ROVs are generally classified into four classes. While rarely used, these classes can be further subdivided into subcategories. These classes are further categorized as Worker ROV, Light Worker ROV, Observation Class ROV, and Micro or Mini ROV. I’ll list other names for these categories below, along with their respective titles.

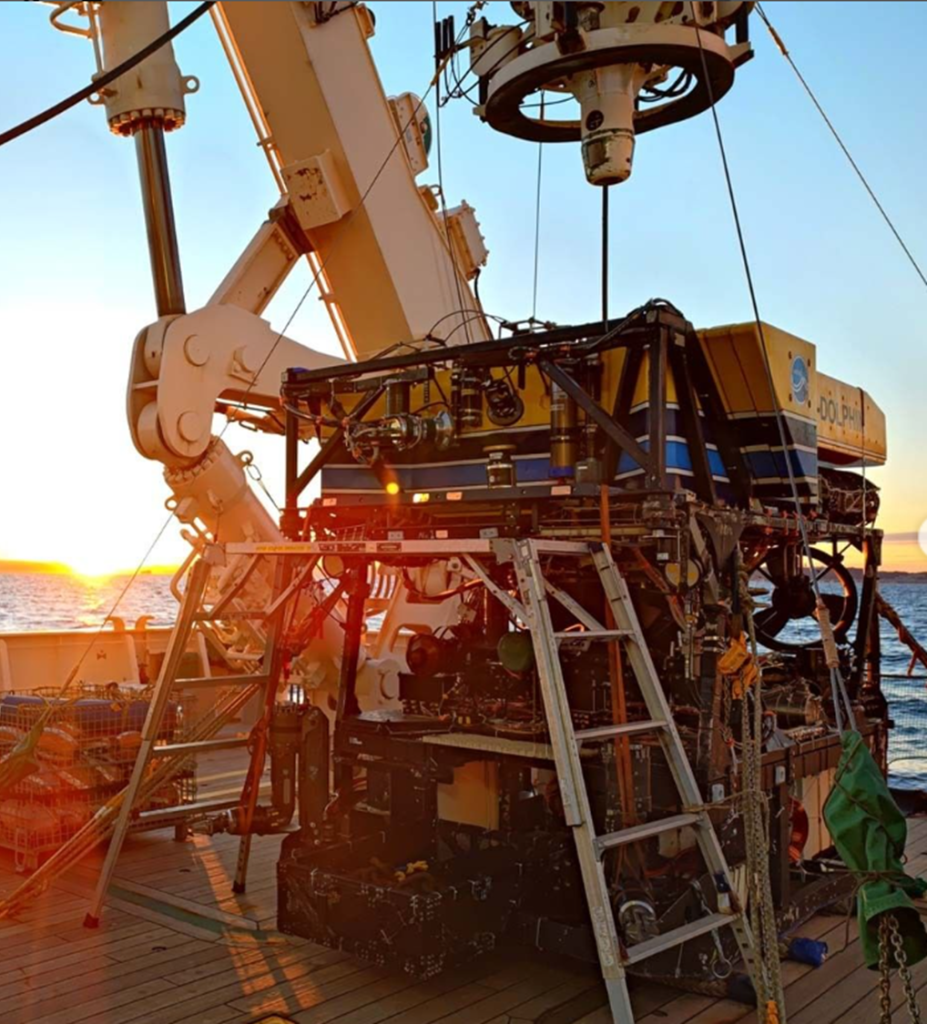

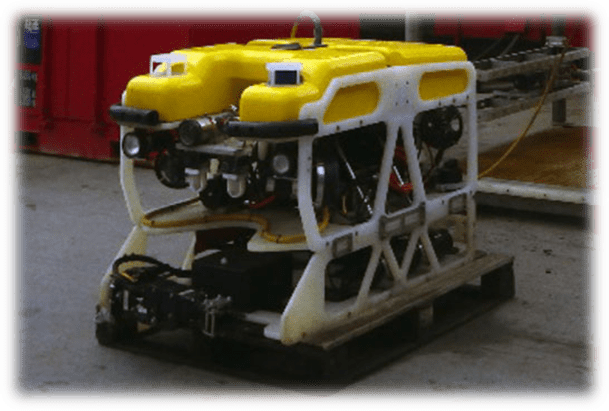

Working Class ROV (Worker Rov/ Work Class)

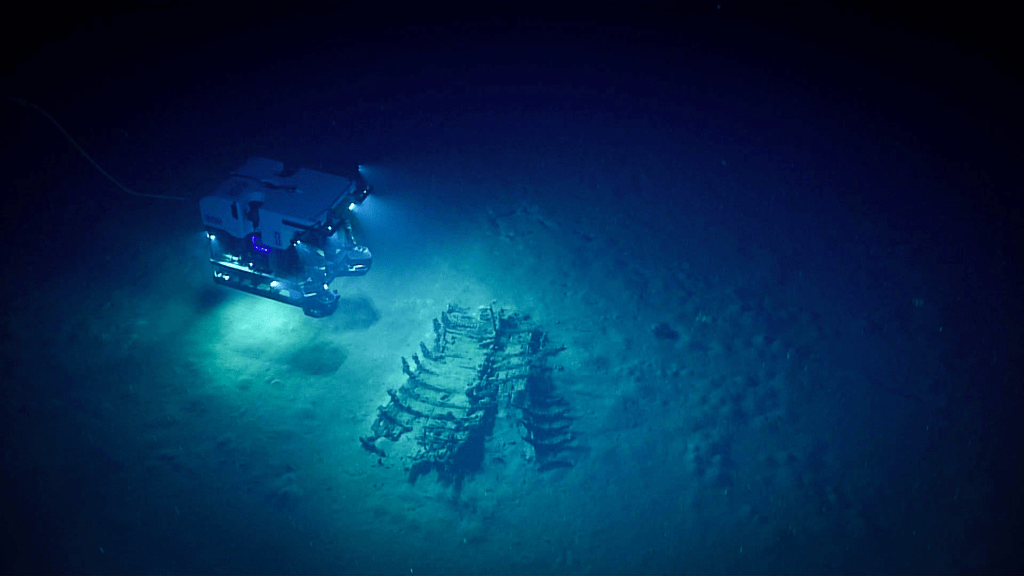

They are used for ocean floor exploration and investigations at depths that divers cannot typically reach. They serve as a safe alternative to divers and are often used in offshore energy projects and deep archaeological exploration. They also include the heavy work class as a subcategory.

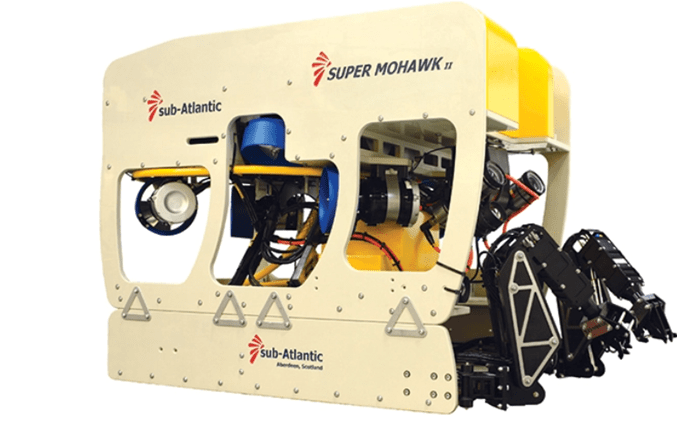

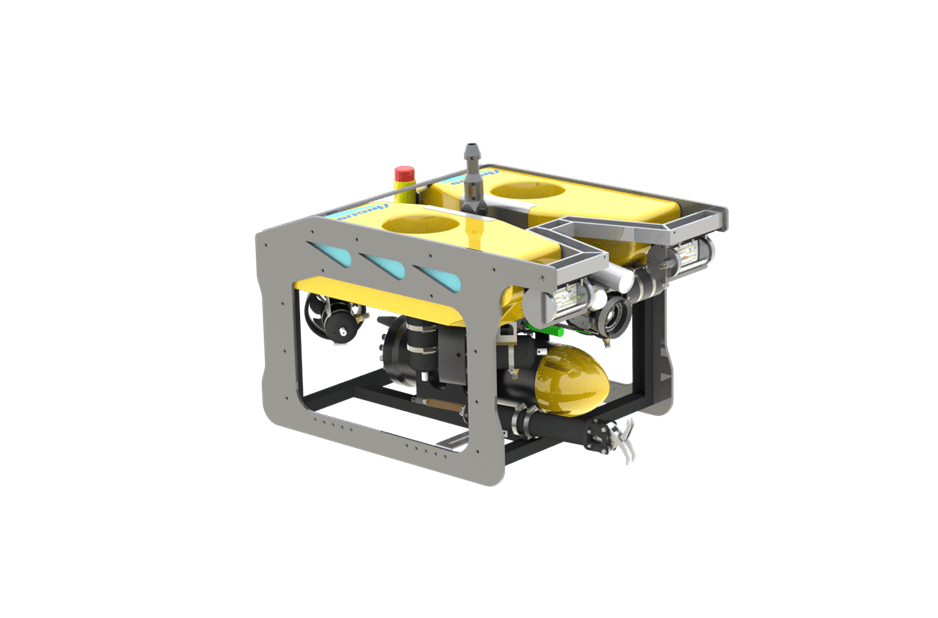

Light Duty ROV (Light Work Class/ Light Duty Work Class)

A light-duty ROV is ideal for medium to deep depths; the ROV is deployed from ships rather than by divers for exploration. It can be used to perform repairs during inspections. Large extensions such as laser scanners or specialized inspection devices and sensors can be added.

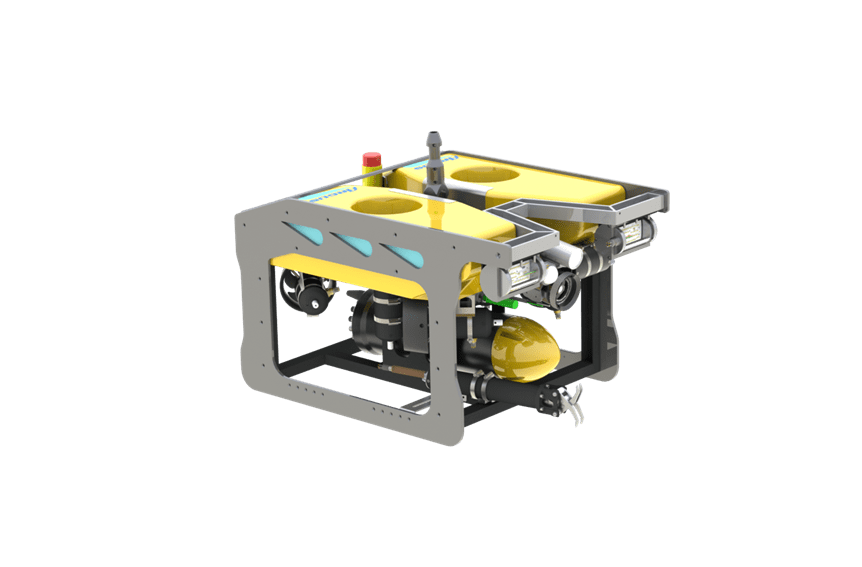

Observation Class ROV (Observation Class/ Inspection Class)

An Observation Class ROV is a small robot used to explore lakes, rivers, and coastal waters at limited depths. They are often used to test water safety before a diver enters the water during missions and inspections. They are versatile vehicles that can be equipped with sonar and specialized sensors.

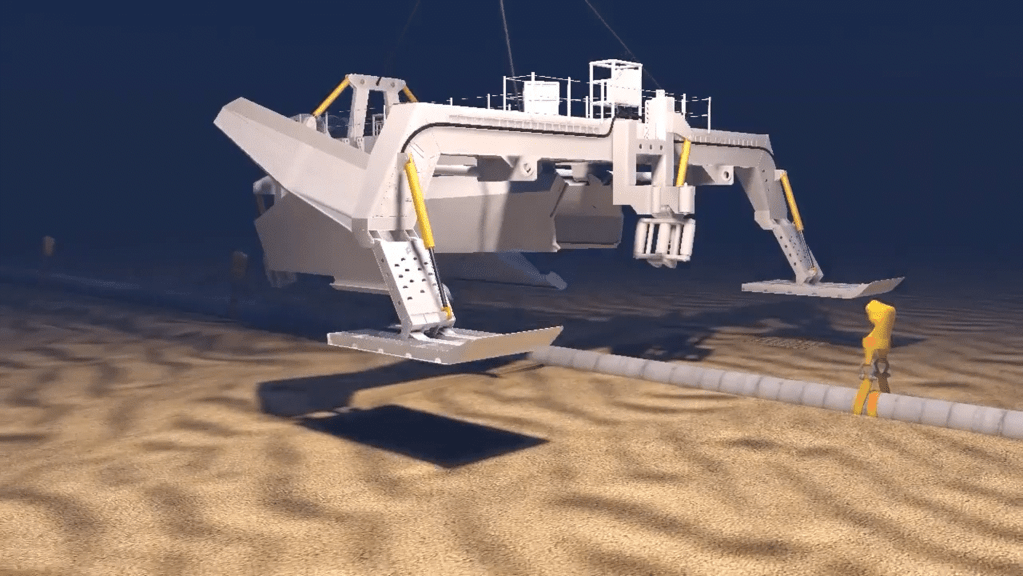

Trenching Class (Trenching/ Burial Class)

Burial class ROVs are designed to bury underwater cables, pipelines, or other infrastructure elements on the seabed. They are typically equipped with powerful water jets or mechanical excavation systems. They play a critical role in offshore construction projects, protecting and securing infrastructure. They can be considered a subcategory of workhorse ROVs.

Micro or Mini ROV

A micro or mini ROV is the smallest class, typically used to inspect hard-to-reach areas at shallow depths and in tight spaces, such as piping systems and underwater infrastructure.

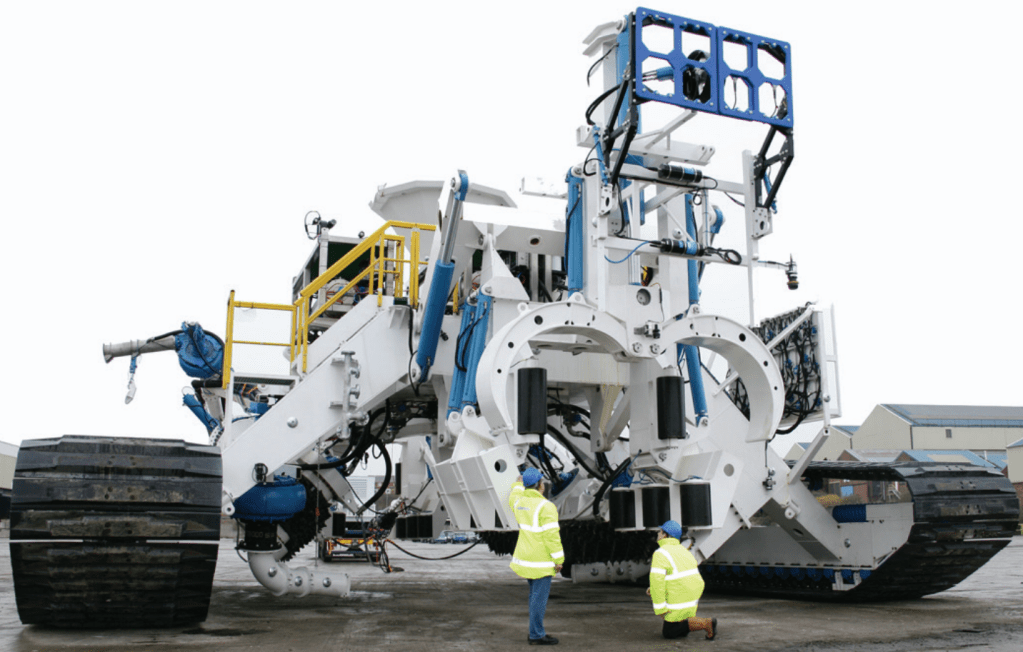

BONUS: Subsea Tractor

They are high-powered underwater vehicles designed to perform heavy infrastructure work on the seabed. They are particularly used for tasks such as burying, stabilizing, and protecting pipelines. Their high-torque drive systems and integrated digging equipment allow them to dig deep trenches in hard ground (including rock). Their advanced flotation systems provide maximum digging power in hard ground while minimizing footprints on soft seabeds. Subsea tractors are a special subcategory of heavy-duty and burrower-class ROVs that play a critical role in energy infrastructure projects and cable/pipe placement operations. They are extremely niche vehicles.

ROV PARTS

Main body (or “pressure housing”): This structure is the central section of the ROV and houses the electronics and controls. It also provides the vehicle’s buoyancy. It’s typically constructed from durable yet lightweight materials like aluminum or titanium and is designed to withstand the pressure exerted by water at operating depth.

Pusher system (thruster arrangement): ROVs have multiple thrusters that allow them to move in different directions. These thrusters can be electric or hydraulic and are usually located at the corners of the main hull.

Control and communication systems: This component includes the electronics, power supplies, and communication modules that enable remote control of the ROV. It also includes sensors such as cameras and sonar used for observation and data collection.

Tether: ROVs are connected to the control station on the surface by a rigid (umbilical) cable. This cable provides both power transmission and data communication. Depending on the need, it can be a single line or a bundle of multiple lines.

Accessories: Depending on the nature of the mission, ROVs can be equipped with various accessories. These include signal and orientation sensors, auxiliary lighting systems, secondary cameras, and underwater manipulator arms. These add-ons enhance the vehicle’s observation, response, and data collection capabilities.

ROV MANUFACTURERS

JAMSTEC

The Japan Agency for Marine Earth Science and Technology is also the manufacturer of KAIKO, the first ROV to reach the bottom of a marina pit in 1995. KAIKO is designed for heavy-duty work with high maneuverability and to support marine biology research.

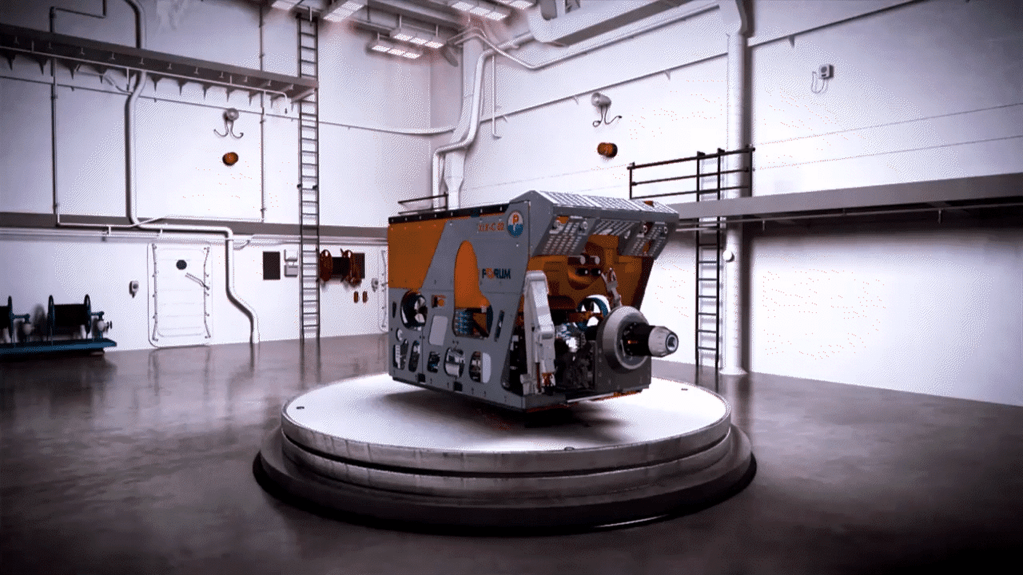

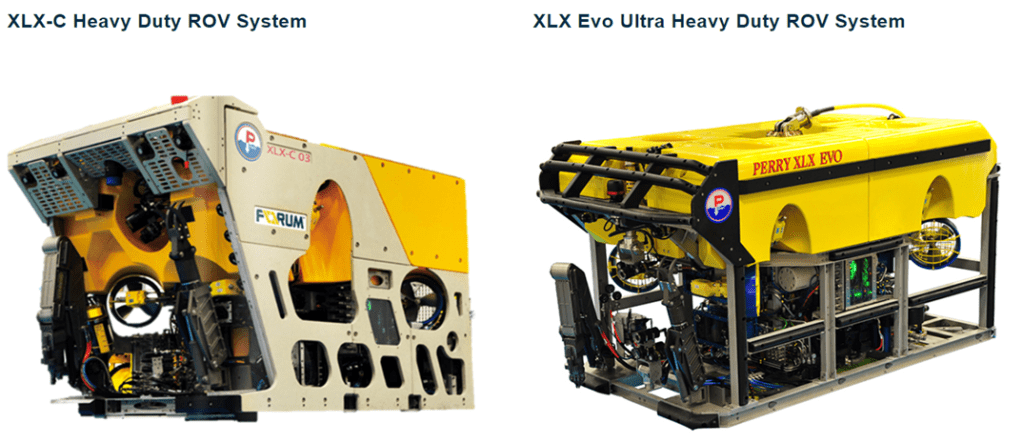

Forum Energy Technologies

A 10-year-old company serving the drilling, subsea, completion, production and infrastructure sectors of the oil and gas industry, producing submarine rescue systems, work-class ROVs, observation ROVs, trenchers and tether systems.

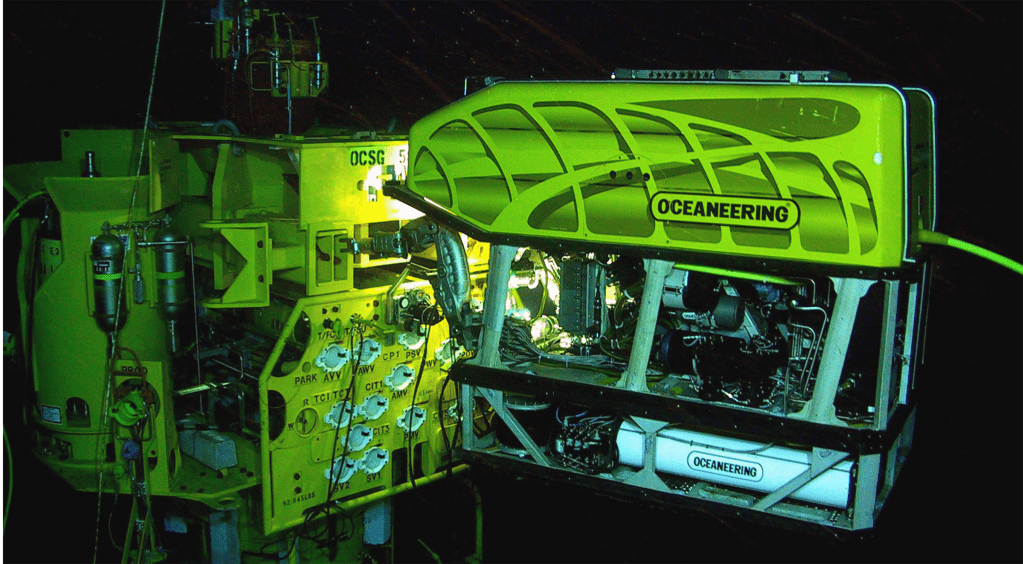

OCEANEERING

They primarily provide engineering services and products to the marine energy industry. Overall, they are a large company serving the defense, entertainment, material handling, aerospace, science, and renewable energy sectors. They operate the world’s largest fleet of installation, operation, and control systems (IWOCS).

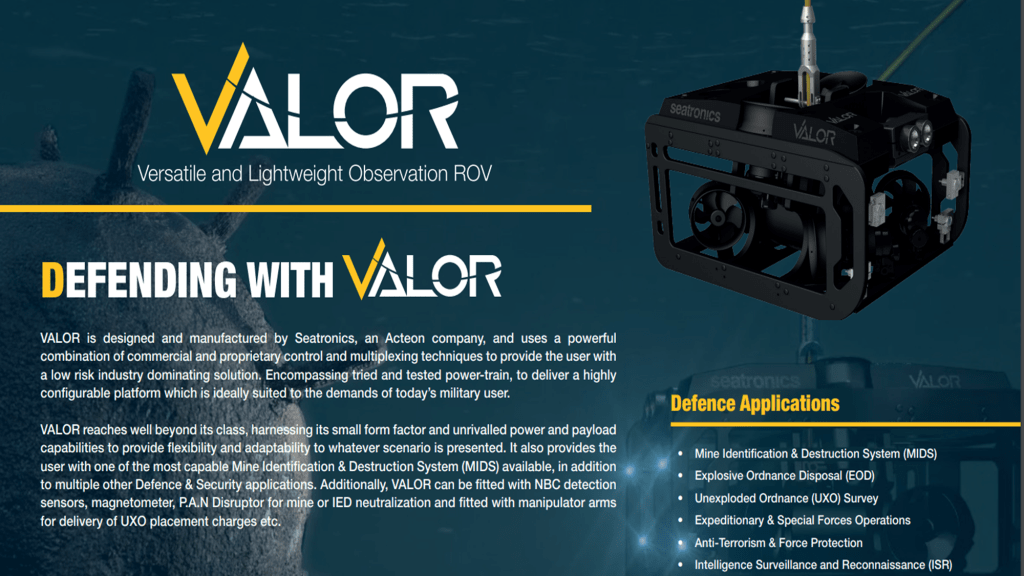

SEATRONİCS

Seatronics provides expert underwater solutions, both in engineering and customer support, covering underwater construction, defense, dredging, IMR, metocean, and renewable energy.

SUBSEA7

subsea7 is a global leader in offshore projects and services for the evolving energy industry. We create sustainable value by being the industry partner and employer of choice for the world’s demanding offshore solutions.

Argus

Argus Remote Systems AS is a manufacturer of electric-driven ROV systems. Our primary customers are in the aquaculture, oil and gas, military, and research industries. Argus offers ROVs, control and workshop containers, cranes, Landing and Recovery Systems (LARS), and Tether Management Systems (TMS). Argus Systems can be equipped with a variety of subsea tools, manipulators, and instruments, both electric and hydraulic.

SMD

SMD is a global designer and manufacturer of underwater remotely controlled and autonomous power and control solutions. Operating across a variety of technology areas, SMD specializes in providing underwater trenching, workhorse ROVs, shipboard equipment, and a range of subsea components through its Curvetech brand.

DEEP TREKKER

Deep Trekker is a technology platform that brings customer-focused robotic inspection solutions to the market, simplifying complex underwater tasks without “service hours” unlike other ROV manufacturers.

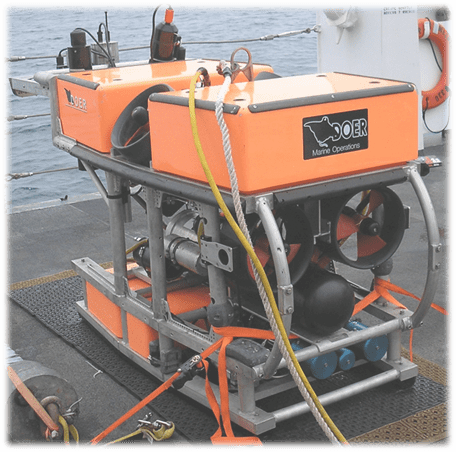

DOER MARİNE

DOER was founded in 1992 as a marine consulting firm, Deep Ocean Exploration and Research. In 1995, the firm expanded its scope and capabilities to include ROVs and subsea vessels. In 2003, DOER continued to grow with a team of innovators, engineers, field operations supervisors, project management staff, technicians, and key consultants. In 2010, DOER partnered with Ocean Innovations to assist with sales and support of ancillary equipment, further enhancing its ability to meet client needs from basic consulting to full analysis and implementation of solutions for the most challenging underwater missions.

NUYTCO

Nuytco Research Ltd. is a global leader in the development and operation of subsea technology. Nuytco and its subsidiary, Can-Dive Construction, have over forty years of experience worldwide. Nuytco designs, manufactures, and operates atmospheric diving suits, submarines, ROVs, lights, thrusters, and other specialized equipment for underwater applications.

BONUS: I can’t make you a ROV pilot, but I can help you feel like one

subROV : Underwater Discoveries

subROV is a game where you operate an observation-class ROV equipped with a manipulator and perform simple tasks in the depths of the ocean. With all its details, it offers an experience that’s close to what you’d feel like as an ROV pilot. I highly recommend it for enthusiasts.

This game has received support from the European Union and the National Science Foundation in the United States and is being developed by a single developer.

All images in this article were taken from the internet.